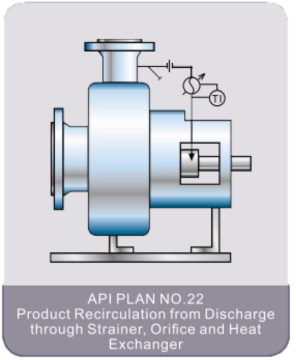

API Plan 22

Overview:

- In API Plan 22 the pumped fluid is recirculated from the pump discharge, through a y-strainer, a flow control orifice, and heat exchanger before being injected into the mechanical seal.

- Think of this API plan as a combination of API Plan 12 and API Plan 21.

- The y-strainer is included in this piping plan to remove occasional large particles.

- The heat exchanger, also referred to as a “seal cooler”, can be either water or air cooled.

Advantages:

- Self-venting

- API Plan 22 provides cooling of the process fluid which is then used to lubricate and cool the mechanical seal.

- The y-strainer removes occasional large particles from the process fluid before it is introduced into the mechanical seal.

Disadvantages:

- Y-Strainer is susceptible to clogging and can potentially restrict or obstruct fluid flow to the seal. Routine maintenance is needed to clean the y-strainer.

- The long term reliability of this piping plan has not been proven.

Best For:

- Hot applications

- Lowering the vapor pressure margin of the pumped fluid

- Clean process fluids – free of contaminants and abrasives. Occasionally subject to large particles.

- Process fluids not susceptible to polymerization or “setting-up” at ambient or lower temperatures

Best Practices:

- Orifice size should be no less than 1/8 in. (0.125 in.).

- Calculate the pressure differential between the pump discharge pressure and the seal chamber pressure to ensure positive flow into the seal.

- Isolation valves should not be installed in the Plan 22 flush piping. If such a valve is installed in the flush line, there poses the risk of it being closed and preventing flow to the seal. In such an event, the seal life will be drastically reduced and subsequently fail due to the lack of cooling and lubrication.

- Routine Maintenance

- Record the temperature of the following. Compare to previous records to trend performance.

- Process fluid into heat exchanger

- Process fluid out heat exchanger

- Cooling water into heat exchanger

- Cooling water out heat exchanger

- Additionally, check the temperature both upstream and downstream of the y-strainer and flow control orifice. If the temperature downstream of is appreciably cooler, the y-strainer or orifice may be obstructed. Immediate action is needed to clear the obstruction. If found obstructed, the seal is likely damaged and needs to be replaced.

- Alternatively, measure the differential pressure across the y-strainer and flow control orifice to determine if they are obstructed.

- Backflush the heat exchanger at least monthly. If cooling water quality is poor, backflush the heat exchanger weekly or more frequently, based on operating experience. Backflushing the heat exchangers will help prevent and mitigate fouling and clogging within the heat exchanger.

- Record the temperature of the following. Compare to previous records to trend performance.